The Yuvidi company has been engaged in metalworking for more than 15 years, the main service of the enterprise is the manufacture of parts, assemblies, mechanisms, cases made of metals, alloys, polymers, composite materials for industrial purposes. The company carries out processing of materials by the method of milling, turning, grinding, welding, laser cutting, as well as heat treatment of materials. Metal processing is actively used in various industries, it solves the problems of customers from the fields of mechanical engineering, medical technology, electrical devices, the petrochemical industry, start-ups.

Metalworking with Yuvidi is:

The company uses its own technologies for metal processing, controlling the process at all stages of production. The company’s managers help clients in the preparation of technical documentation for parts, recommend changes in the drawings of future products, optimize production times in order to improve the properties of finished products during use. Yuvidi’s personnel undergo annual advanced training to work with more sophisticated high-tech equipment, as the production base of the enterprise is constantly growing. It is thanks to the staff of qualified employees, a fleet of high-precision equipment, well-established production technology that metalworking in Yuvidi is carried out on time.

Milling work on metal

Customers use parts from our production in medical instruments,

startups, petrochemical and electrical industries. After graduation

cooperation, the customer can always call Yuvidi and consult

about the properties and characteristics of products or new planned parts. Company

delivers parts to many countries around the world, if required by the customer.

The production is located in Minsk and meets all modern technological

standards.

We are also engaged in complex metalworking and manufacturing followed by

protective coating. More information about these services can be found here.

View examples of milled products on our page

work. Contact Yuvidi and our manager will call you back during the day.

- We process material with an accuracy of 5 microns

- Machine tools of the German manufacturer DMG MORI

- Delivery outside Belarus

Metal processing

Metalworking on CNC machines is a process that involves the use of software to control equipment, especially characteristic of CNC metalworking at the present stage. The algorithms of the CNC machine allow you to increase the machining accuracy, which allows you to process complex parts faster.

Yuvidi processes more than 50 types of metals and alloys from which rare expensive metals, plastic polymers, composite materials. The company also provides services of grinding, electroplating, processing of fiberglass. Juvidi uses 5-axis machine tools that machine the metals of the products with greater precision and also reduce the time spent in metalworking.

Metalworking in Belarus

Metalworking is a complex technical process that should be entrusted to real professionals with extensive experience. Yuvidi has been working in metalworking in Belarus, as well as in the near abroad for more than 15 years. The details that are manufactured by the company contribute to import substitution and help to carry out the most complex projects in the industrial field, which are so important for our customers. Metalworking at Yuvidi is:

- exact adherence to the terms of metalworking;

- professional staff of managers and performers with

- many years of experience in metal processing;

- modern equipment from a premium manufacturer

- metalworking machines

- delivery of parts outside the Republic of Belarus.

Milling

Juvidi has been working on milling machines for over 20 years. During this time, we have prepared a production base of CNC milling machines and universal milling equipment. The company employs more than 50 qualified specialists: locksmiths, CNC machine operators, designers, technologists and many others. Almost every employee undergoes refresher courses to work with more complex technological equipment. Milling work in Juvidi is carried out with accuracy tolerances up to 5 microns and its own quality control system.

Turning

Are you looking for where to order at a reasonable cost operational metal processing on CNC machines in Minsk? Our company Yuvidi performs turning work to order of any degree of complexity. One of our main advantages over competitors is the presence of our own powerful turning production. Transferring the technical equipment of our company gives us the opportunity to carry out an impressive range of metalworking services. We work with a wide variety of metals and alloys (steel, cast iron, titanium, bronze, etc.). We are successfully engaged in the production of metal structures of any shape on the most favorable terms for our clients.

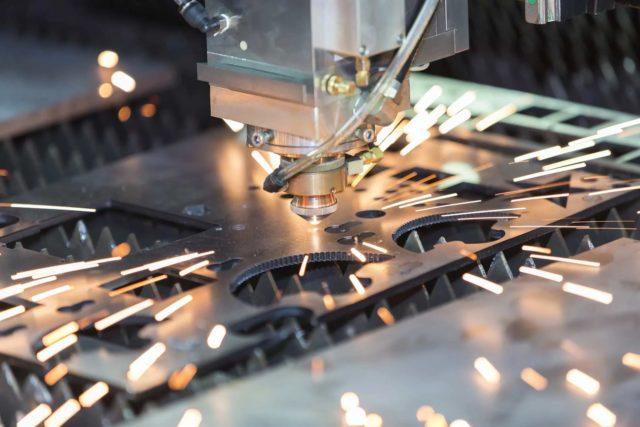

Laser cutting

Laser cutting is one of the methods for cutting metal with a high power machine.

The mechanical effect on the metal is reduced, so it retains its strength and rigidity, cuts quickly, keeping a minimum of burrs and deformations.

Grinding

Sanding is a popular procedure for removing a certain small layer from a metal product or any other material. Often, grinding is used to give the product the most accurate dimensions that could not be achieved by machining the workpiece on a machine.

Welding

Welding is the process of influencing a metal using special equipment that heats and joins the metal at the atomic level.

Parts manufacturing

The Juvidi company manufactures and processes products and components from various materials, but the most common types of parts are metal. Manufacturing metal parts is a time consuming process that requires special skills, tools and clear recommendations. Manufacturing of parts is often the machining of material to shape and size for specific applications.

Fiberglass processing

Heat treatment is a method of changing the properties of products using the effect of temperature (heating, holding, cooling). With the help of heat treatment, materials become stronger, a change in molecular composition occurs.

The Juvidi company carries out heat treatment in modern ovens that maintain temperatures up to 1300 ° C. Thanks to the equipment, the company fulfills any orders to change the properties of metals for various customer requests.

15 years

in metalworking for

clients from various fields

+4000

items and units per shift

10+

machining centers in our

production base

5 - axes

workpieces can be processed

simultaneously using 5-axis equipment